Mattress Tips

February 2026How To Choose The Best Mattress If You’re Overweight

It’s incredibly frustrating that all mattresses for heavier sleepers are built with the firmest, most robust support materials. Yet, there is no discussion of comfort or upholstery layers to improve a better night’s sleep.

That single “firm” mattress sitting at the back of the showroom wasn’t designed for your needs; it’s simply the only option retailers stock when they haven’t bothered to engineer proper solutions. The weight limits printed in tiny font on specification sheets reveal the uncomfortable truth: 90% of retail mattresses stop supporting you properly beyond 18 stone per sleeper, leaving an enormous segment of the population with inadequate options.

This guide explains what heavier sleepers actually need, why conventional retail mattresses fail, and how to find mattresses engineered for proper long-term support rather than short-term compromises.

The weight limit problem retailers won’t discuss

Standard retail mattresses typically support up to 18 stone (115kg, 252lbs) per individual sleeper, with combined weight limits of around 30 stone (190kg) for couples. These aren’t arbitrary marketing numbers; they represent genuine engineering constraints in how mattresses are constructed.

Spring gauge, upholstery density, and overall build quality determine weight capacity, and budget-to-mid-range mattresses aren’t engineered beyond these limits.

What happens when you exceed these weights? The mattress doesn’t immediately collapse, which is precisely why retailers continue selling them to heavier customers. Instead, degradation accelerates dramatically.

Springs compress beyond their elastic limit and lose tension. Upholstery layers compact faster than designed. Permanent body impressions develop within months rather than years. The mattress that felt supportive in the showroom develops a visible sag exactly where you sleep, forcing your spine into unnatural positions and causing the back pain, hip discomfort, and poor sleep quality that brought you to mattress shopping in the first place.

Most retailers won’t voluntarily disclose weight limits because doing so would disqualify their entire range for a significant customer segment. When pressed, they’ll claim their firmest model “should be fine” or suggest the problem lies with your weight rather than their inadequate product engineering. This is commercial nonsense designed to close a sale rather than solve your sleep problems.

Weight categories and realistic expectations

For UK shoppers, here’s how weight categories translate and what each requires:

| Weight Range | Spring Gauge Required | Minimum GSM | Construction Type | Key Requirements |

|---|---|---|---|---|

| 18 to 20 stone (115 to 127kg) |

1.6mm minimum | 2000+ GSM | Two-sided essential | Upper limit of standard mattresses. Extra firm tension required. One-sided models wear out in 3-4 years. |

| 20 to 25 stone (127 to 159kg) |

1.8mm gauge or dual layer |

2500+ GSM | Specialist construction | Standard retail mattresses are inappropriate. Need reinforced springs and manufacturers who explicitly rate for this weight. |

| 25 to 30 stone (159 to 190kg) |

1.9 to 2.0mm | 3000+ GSM | Bariatric specialist | Extra firm spring systems. High-density foams or Latex. Minimum depth of 12-14 inches required. |

| Above 30 stone (190kg+) |

2.0mm+ or continuous coil |

3500+ GSM | Purpose-built bariatric | Ultra reinforced pocket spring arrays or continuous coil systems—commercial grade high density foams. |

Why “just buy firm” doesn’t work.

The default retail advice for heavier sleepers is infuriatingly simple: buy the firmest mattress available. This ignores everything about how bodies actually interact with sleep surfaces and why people of different weights need different support profiles.

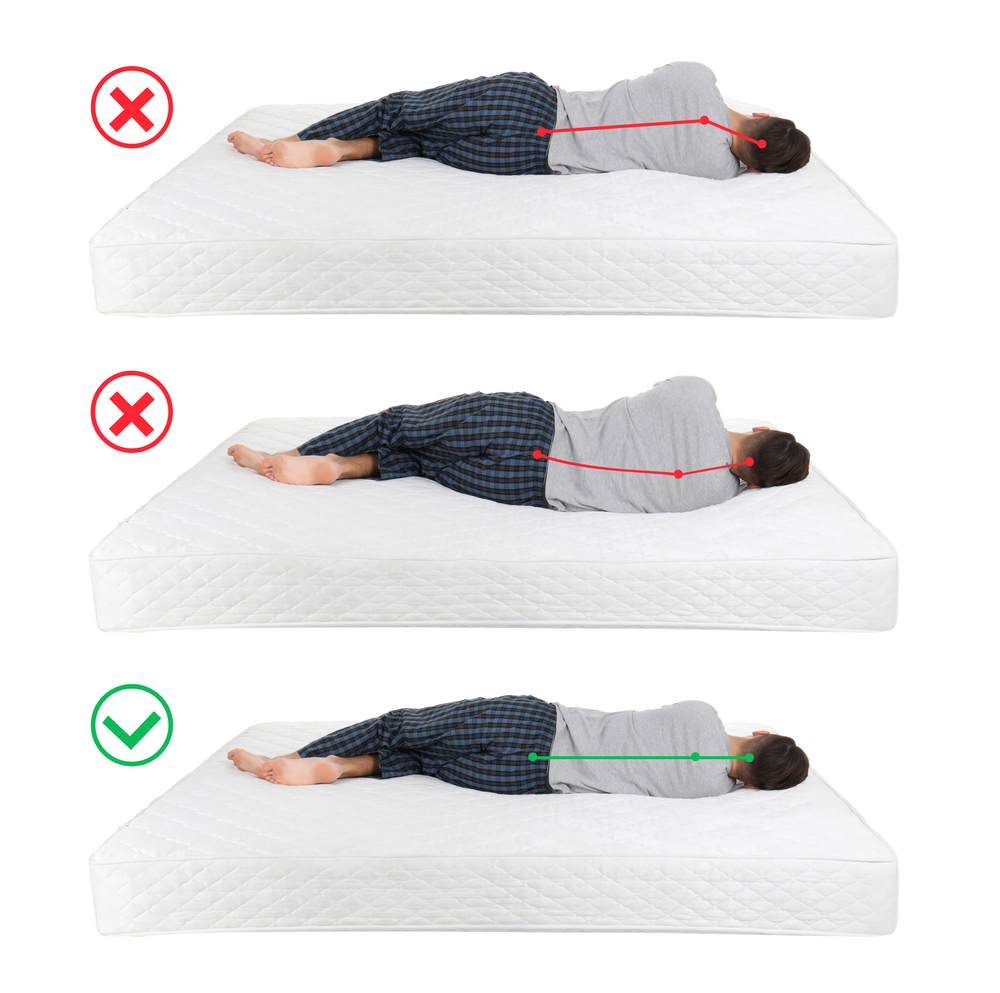

A genuinely firm mattress provides minimal surface cushioning whilst maintaining strong underlying support. For a 12 stone side sleeper, firm feels supportive. For a 22-stone side sleeper on that same mattress, “firm” means your shoulders and hips can’t sink enough to maintain spinal alignment.

You’re forced to sleep on the broadest points of your body rather than having pressure distributed across a larger surface area. This creates the exact pressure-point problems that firm mattresses are supposed to solve.

The technical issue is compression depth. Heavier bodies compress upholstery layers more deeply, meaning you reach the firm support layer faster. A mattress that feels medium to a lighter person can feel very firm to a heavier person, and a mattress marketed as firm can feel rock-solid and uncomfortable.

The solution isn’t maximum firmness; it’s adequate upholstery thickness paired with properly gauged support systems.

Sleeping position requirements for heavier sleepers

Back sleepers (heavier builds)

- Support needed: Firm to extra firm to prevent lumber region sagging

- Comfort requirement: Sufficient surface cushioning to avoid pressure on the shoulder blades and lower back

- Recommended specs: 2000+ GSM upholstery over extra firm springs (1.6 to 1.8mm gauge)

Side sleepers (heavier builds)

- Challenge: Most difficult position for heavier people due to weight concentration on shoulders and hips

- Balance required: Firm enough to support weight without bottoming out, but soft enough to allow proper shoulder and hip alignment

- Recommended specs: 3000+ GSM upholstery with medium firm to firm springs (1.4 to 1.6mm gauge)

- Avoid: Ultra firm models that create pressure points

Stomach sleepers (heavier builds)

- Support needed: Firm to extra firm to prevent midsection sagging and spine hyperextension

- Comfort layers: Thinner layers work better, with emphasis on spring firmness

- Recommended specs: Extra firm pocket springs with 1500 to 2000 GSM upholstery maximum

Combination sleepers (heavier builds)

- Challenge: Hardest category to fit properly, needs responsive support across multiple positions

- Recommended specs: Medium firm springs with generous natural fibre upholstery that remains supportive

- Often benefits from: Custom spring tension specification.n

Spring specifications that actually matter

Spring count marketing dominates mattress retail, but for heavier sleepers, spring gauge matters infinitely more than spring count. Let’s cut through the specifications that determine whether a mattress will properly support you.

Spring gauge and wire thickness

Spring gauge refers to the wire diameter measured in millimetres. Here’s how different gauges match to body weight:

| Spring Gauge | Tension Rating | Suitable Weight Range | Availability |

|---|---|---|---|

| 1.28mm | Soft | Up to 12 stone | Completely inappropriate for heavier builds, regardless of spring count |

| 1.4mm | Medium | 12 to 16 stone | Standard in most mattresses. Begins feeling too soft at 18 stone |

| 1.6mm | Firm | 16 to 20 stone | Minimum specification for anyone above 18 stone |

| 1.8mm | Extra Firm | 20 to 25 stone | Most high street retailers don’t stock this gauge |

| 1.9 to 2.0mm | Bariatric | 25 stone and above | Only available from specialist manufacturers |

The difference between 1.4mm and 1.6mm wire seems trivial until you understand the physics. Spring resistance increases exponentially with wire diameter, not linearly. A 1.6mm spring is dramatically firmer than a 1.4mm spring, not just slightly firmer.

This is why proper gauge matching to body weight is critical.

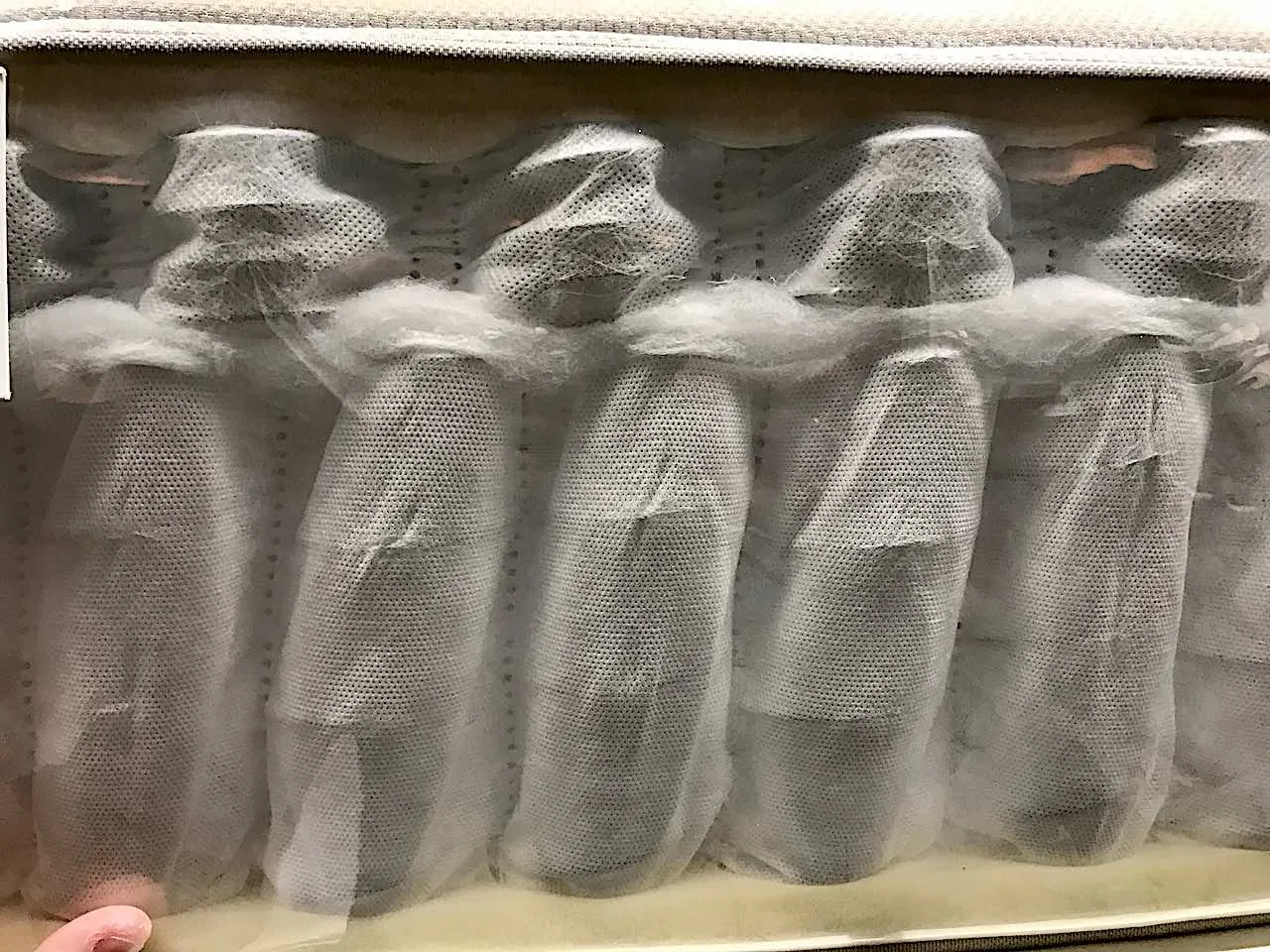

Calico vs spunbond pocket springs for durability

For heavier sleepers putting more stress on spring systems, pocket material affects longevity significantly:

| Pocket Type | Construction | Cost | Lifespan (Heavy Sleepers) | |

|---|---|---|---|---|

| Spunbond Polyester | Glued together during manufacture | Less expensive | 6 to 8 years | |

| Calico CottonHand-tied | d with twine | Significantly more expensive | 10 to 12+ years |

If you’re above 20 stone, calico springs aren’t a luxury; they’re a durability necessity that significantly affects cost per year of ownership.

Upholstery GSM and compression resistance

Total upholstery GSM (grams per square metre) quantifies the combined weight of all comfort layers. For heavier sleepers, GSM determines whether comfort layers maintain their structure or bottom out, leaving you sleeping directly on springs.

| GSM Range | Suitable Weight | Performance for Heavy Sleepers | Material Requirements |

|---|---|---|---|

| Under 1500 GSM | Up to 16 stone only | Insufficient – compresses completely | Avoid entirely if above 16 stone |

| 1500 to 2000 GSM | 16 to 20 stone | Minimum acceptable | Must use dense natural fibres (Wool, Cotton), not soft polyester batting |

| 2000 to 3000 GSM | 18 to 25 stone | Appropriate range | Natural fibre content is increasingly important for resilience under compression |

| 3000+ GSM | 25+ stone | Premium comfort | Substantial comfort layering with high natural fibre content |

Material composition matters as much as total weight. 2000 GSM of cheap polyester performs completely differently from 2000 GSM of British fleece Wool and Cotton. Natural fibres resist compression better, wick moisture more effectively, and maintain loft longer under heavy use.

Mattress thickness and support depth

Mattress depth affects how far you compress before reaching maximum support, which is critical for heavier builds.

| Mattress Depth | Suitable Weight Range | Performance | Additional Notes |

|---|---|---|---|

| Under 25cm (10 inches) |

Not suitable above 18 stone | Too shallow | You’ll compress through comfort layers too quickly, feeling like you’re sleeping on springs directly |

| 25 to 30cm (10 to 12 inches) |

18 to 23 stone | Minimum acceptable | Provides adequate compression depth if using an appropriate spring gauge and upholstery density |

| 30 to 35cm (12 to 14 inches) |

20 to 28 stone | Ideal range | Accommodates proper comfort layering whilst maintaining support structure |

| 35cm+ (14 inches+) |

28+ stone | Bariatric category | Requires deep-pocket sheets and proper bed frame clearance |

Thicker doesn’t automatically mean better, but insufficient depth is a guarantee of poor performance for heavier sleepers. The mattress must have physical space for adequate comfort layers above robust support systems.

Two-sided construction: essential, not optional.

Two-sided (also called double-sided or turnable) construction allows you to flip and rotate the mattress, distributing wear across four surfaces instead of one. For heavier sleepers who put more stress on materials, this isn’t a premium feature; it’s fundamental to reasonable longevity.

A one-sided mattress for a 22 stone sleeper typically develops permanent body impressions within 3 to 4 years because all compression occurs in the same upholstery layers. A two-sided mattress of equivalent quality extends this to 8 to 10 years by allowing regular rotation to fresh surfaces.

The mathematics are straightforward. A one-sided mattress costs perhaps £1,200 and lasts 4 years, delivering a £300 per year cost. A two-sided mattress costs £2,000 and lasts 10 years, delivering a £200 per year cost whilst providing superior comfort throughout its lifespan.

Most retailers have abandoned two-sided construction because it costs more to manufacture. They sell one-sided models at similar prices to historical two-sided alternatives, pocketing increased margins whilst customers replace mattresses more frequently.

For heavier sleepers, who already stress materials more than lighter users, accepting one-sided construction guarantees premature replacement.

Dual tension solutions for couples

Weight disparities between partners create genuine challenges when selecting a mattress. If one partner weighs 13 stone and the other weighs 22 stone, no single mattress tension works optimally for both.

The lighter partner needs medium springs to avoid feeling like they’re sleeping on a board. The heavier partner needs firm to extra firm springs to prevent sagging.

Retailers typically respond by recommending firm models, ensuring the heavier partner gets adequate support, whilst the lighter partner gets an unnecessarily hard surface. This “compromise” means both people sleepsub-optimallyy, which isn’t actually a compromise at all.

Zip and link dual tension mattresses

Zip-and-link mattresses join two separate mattresses along their length using concealed zippers, creating what looks and functions like a single mattress whilst allowing different spring tensions on each side. This enables genuinely optimised sleep for both partners.

The construction uses matching depths to prevent a ridge down the centre, with coordinated upholstery specifications so the surface feels uniform despite different spring tensions underneath. A mattress topper can further unify the sleep surface if desired.

For couples with significant weight differences, zip-and-link construction eliminates the “rolling together” problem, where the lighter partner gravitates toward the sagging depression created by the heavier partner. Each side maintains its engineered shape independently.

Natural fibres vs synthetic materials

For heavier sleepers, material choice significantly affects both comfort and longevity:

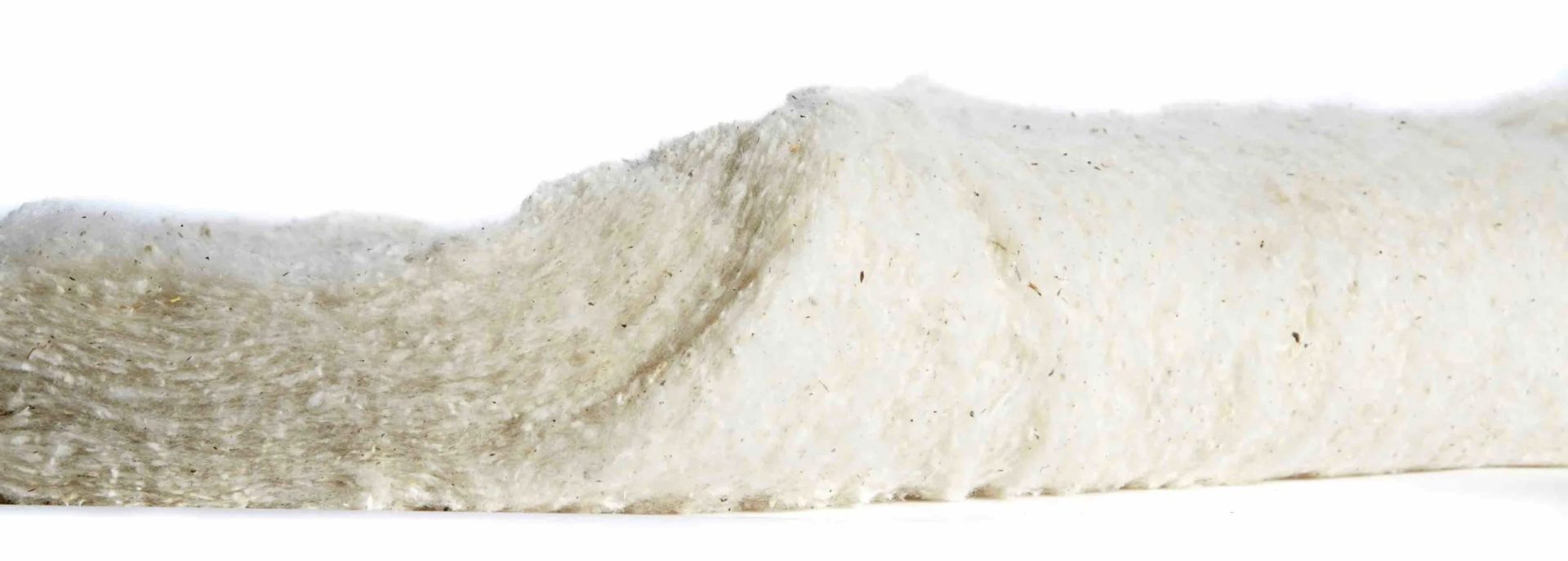

Wool

- Resilience: Compresses then springs back to its original loft repeatedly

- Benefits: Natural temperature regulation and moisture wicking

- Performance: Maintains loft under heavier use

- Recommended GSM: 1000 to 1500 GSM provides substantial comfort without bottoming out

Cotton

- Character: Breathable and durable, provides firmer support than Wool

- Best type: Rebound Cotton pads resist permanent compression better than standard batting

- Comfort: Remains comfortable whilst offering firmer support

Mohair

- Quality level: Premium natural fibre

- Durability: Outstanding resilience, more expensive than Wool

- Performance: Maintains loft exceptionally well under continuous heavy compression

Horsetail

- Firmness: Extremely firm natural fibre providing robust support

- Usage: Often used in premium mattresses for heavier sleepers

- Benefit: Provides firm comfort layers that won’t compact over time

Polyester

- Cost: Inexpensive and widely used

- Drawback: Compresses permanently under heavy use

- Warning: Budget mattresses using primarily polyester upholstery will flatten quickly for heavier sleepers

Memory Foam

- Contouring: Conforms to body shape closely

- Drawbacks: Retains heat, provides less support than natural fibres for heavier builds

- Better option: High-density memory Foam (50kg/m³ or higher) performs better but costs significantly more

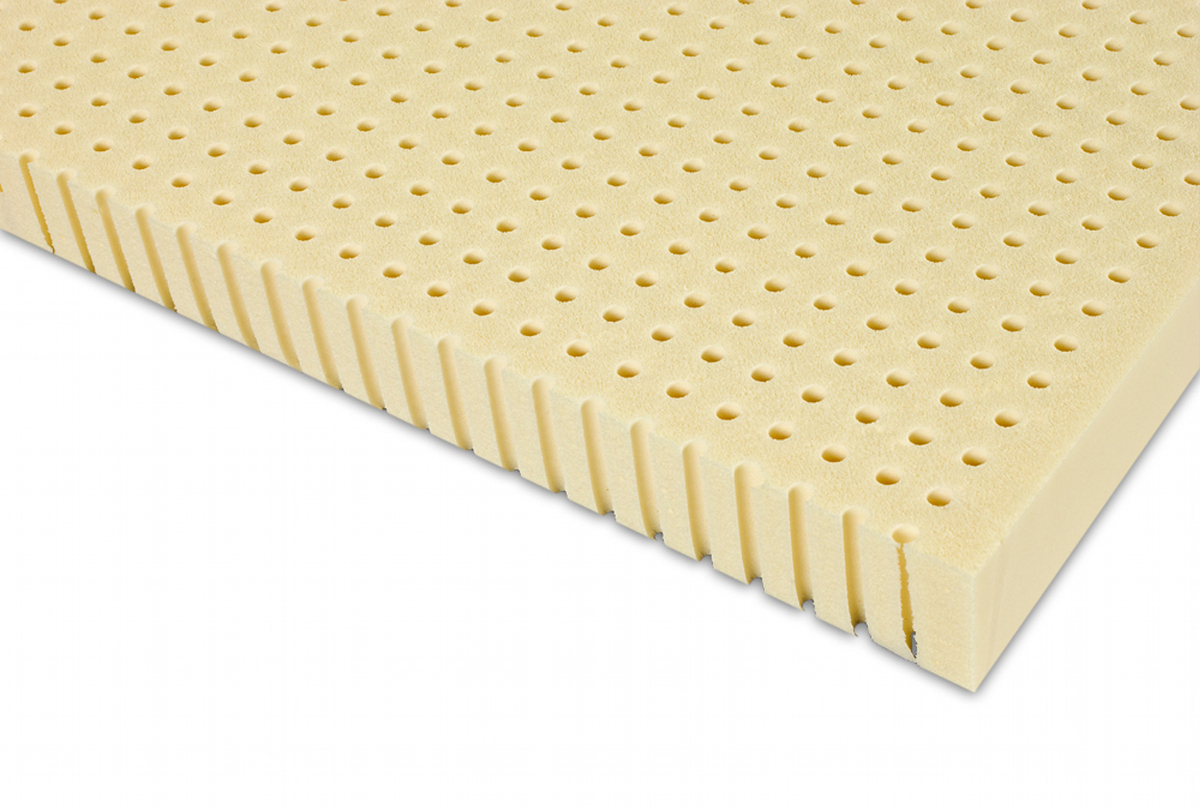

Latex (natural)

- Resilience: Excellent support and pressure relief

- Best type: Dunlop Latex is denser than Talalay

- Performance: Maintains structure under heavy compression whilst providing pressure relief

For heavier sleepers prioritising longevity, natural fibre mattresses with high GSM specifications outperform synthetic alternatives in maintaining comfort and support over time.

Edge support and usable sleep surface

Edge support becomes particularly important for heavier sleepers because inadequate perimeter construction creates an unusable border around the mattress, making sitting or lying near the edgefeels unstable.

Quality edge support uses:

ReinforcedFoam perimeters

- Construction: High-density Foam encasing the mattress perimeter

- Thickness: Typically 2 to 3 inches thick

- Benefit: Prevents edge collapse when sitting or sleeping near the mattress border

Full perimeter spring support

- Design: Pocket springs extending to the absolute edge

- Advantage over budget models: Standard mattresses stop springs 4 to 6 inches short

- Result: Even support across the entire sleeping surface

Upholstery edge reinforcement

- Construction: Proper edge stitching and reinforcement

- Purpose: Prevents upholstery layers from sliding away from mattress edges under stress

For heavier sleepers, compromised edge support means losing 6 to 8 inches of usable width around the entire mattress perimeter. On a king-size mattress, poor edge support can reduce the effective sleeping area to roughly twice that of a twin.

This matters particularly for larger builds requiring more physical space.

John Ryan specialist mattresses for heavier sleepers

Having explained what heavier sleepers actually need, here are three John Ryan mattresses engineered specifically for weights above standard retail limits, with complete specification transparency.

Resilience 2 (£2,110 King)

Our Resilience range uses a dual-construction approach designed specifically for sleepers over 20 stone who exceed standard mattress weight limits. Rather than simply using firmer springs and calling it solved, the Resilience 2 separates support and comfort functions for long-term durability.

What’s inside

Support layer (permanent base)High-density

- y reflexFoamm base layer providing firm, stable support

- Commercial-grade polyurethane Foam engineered for weight distribution

- Firm compression resistancepreventsg base layer failure

- 27cm depth base section

Comfort layer (removable topper)

- 8cm Hybrid Latex or memory Foam topper

- Higher density specification than standard toppers

- Removable and replaceable design

- Machine washable cover

Complete specifications

- Total depth: 35cm (approximately 14 inches)

- Weight capacity: 25 to 30 stone per sleeper

- Combined weight capacity: 50 to 55 stone

- Suitable for: Very heavy sleepers, bariatric applications

- Feel: Firm to extra firm, depending on topper selection

Why does this constructionworks for heavier sleepers

The separable design addresses the fundamental problem heavier sleepers face: comfort layers wear faster than support systems. With conventional mattresses, when the comfort layers compress permanently, you replace the entire mattress, even though the springs remain serviceable.

The Resilience 2 isolates wear to the replaceable topper, extending the base unit’s lifespan to 12+ years whilst allowing topper replacement every 4 to 6 years.

The commercial-grade Foam base provides consistent support that doesn’t sag or leave permanent impressions under heavier weights. This eliminates the body impressions that develop in standard pocket spring mattresses when used above their weight rating.

Artisan Bespoke (Extra Firm) (£3,145 King)

For heavier sleepers wanting natural fibre comfort with robust pocket spring support, the Artisan Bespoke in extra firm spring tension (custom order) provides 100% natural upholstery overcalico-encased springs engineered for extended weight ranges.

What’s inside

- 2508 calico encased pocket springs in dual tiers (1.6mm to 1.8mm gauge, extra firm specification)

- 1000 GSM British Alpaca fibres

- 1200 GSM Swaledale Wool

- 1200 GSM Horsetail

- 1000 GSM organic flax

- Hairproof cambric covers

- Total: 4400 GSM upholstery (100% natural fibre)

- Two-sided, fully turnable construction

- 30 to 33cm depth

- Custom extra firm spring tension for heavier sleepers

Weight capacity

- Individual sleeper: Up to 22 to 23 stone in extra firm specification

- Combined weight: Up to 42 to 44 stone

Why we recommend it

The Artisan Bespoke combines genuinely premium natural materials with engineering appropriate for heavier builds. Thedual-tierr spring system (2508 springs total) provides exceptional support distribution, whilst the 4400 GSM natural fibre upholstery maintains comfort without bottoming out.

Horsetail and organic flax both offer outstanding compression resistance, preventing the permanent indentation that develops in softer natural fibres under heavy use. TThe two-sidedconstruction extends lifespan to 12 to 15 years with proper rotation, making the higher initial cost economically sensible when calculated per year of ownership.

Critically, we can customise spring tension beyond our standard range. Whilst our standard Artisan Bespoke uses 1.4mm gauge springs, we also manufacture extra-firm versions in 1.6mm to 1.8mm gauge, specifically for heavier sleepers.

This customisation isn’t advertised on the website because it requires direct specification consultation, but it’s precisely this type of tailored engineering that heavier sleepers require.

Artisan Bespoke 004 (£2,860 King)

For heavier sleepers seeking 100% natural construction with firm support, the Artisan Bespoke 004 provides calico springs and natural fibre upholstery at a more accessible price point than the full Artisan Bespoke.

What’s inside

- 1600 calico encased pocket springs (1.6mm gauge, firm specification as standard)

- 1000 GSM blended British fleece Wool and Cotton

- 400 GSM soft Bamboo

- 1200 GSM pure Horsetail

- 1000 GSM bonded British fleece Wool and Cotton

- Hairproof cambric covers

- Total: 3600 GSM upholstery (100% natural fibre)

- Two-sided, fully turnable construction

- 27 to 30cm depth

- Firm feel (can be specified firmer on request)

Weight capacity

- Individual sleeper: Up to 20 to 21 stone in standard firm specification

- Combined weight: Up to 38 to 40 stone

Why does it bridge the gap

The Artisan Bespoke 004 sits between our Artisan Naturals (which tops out around 1-19 stone) and the full Artisan Bespoke (engineered for 22+ stone). It uses 1.6mm gauge springs as standard, providing firmer support than our medium-tension models whilst remaining more affordable than the dual-tierr spring construction in the full Bespoke.

The 3600 GSM natural upholstery with Horsetail provides robust compression resistance without excessive thickness that might feel too soft for heavier builds. Two-sided construction and calico springs ensure a lifespan of 12+ years with proper care.

For sleepers in the 18-21 stone range who want natural fibres and proper engineering without bariatric specifications, this is our recommended starting point.

Bed frame and base requirements

Heavier sleepers putting more weight on sleep systems need proper foundation support that standard bed frames may not provide.

Foundations to avoid

Slatted bases with wide gaps

- Gap size problem: Slats spaced more than 5cm apart lack adequate support

- Mattress impact: Mattress sags between gaps

- Result for heavy sleepers: Dramatically accelerated wear

Budget metal frames

- Construction weakness: Lightweight tubular steel bends and distorts

- Performance issues: Creaking noise under heavier weights

- Safety concern: Potential collapse with heavy use

Platform bases without centre support

- Size requirement: Double and larger need centre support beams to prevent bowing

- Heavy sleeper needs: Reinforced centre supports with additional legs

- Failure mode: Base bowing creates mattress sag

Recommended foundations

Solid platform divans

- Support type: Uniform support across the entire mattress base

- Key benefit: Eliminates sagging between slats

- Weight distribution: Even distribution rather than concentrated stress points

- Best for: Maximum longevity and weight capacity

Reinforced slatted frames

- Slat spacing: Maximum 5cm gaps between slats

- Slat width: Minimum 5cm wide slats

- Structure: Reinforced cross beams for support

- Size requirement: Centre support legs are essential for king-size and larger beds

Adjustable bases for heavy sleepers

- Critical check: Verify weight capacity explicitly before purchase

- Avoid: Budget models rated for 20 stone fail quickly with heavier use

- Look for: Commercial-grade motors and reinforced frames

- Minimum rating: 30+ stone per side for heavier sleepers

The mattress represents half the sleep system. Pairing a £2,500 mattress engineered for heavier sleepers with a £200 budget bed frame guarantees premature failure regardless of mattress quality.

Maintenance for maximum longevity

Heavier sleepers, who stress materials more than lighter users do, benefit significantly from proper maintenance, which extends the mattress’s lifespan.

Rotation and flipping schedTwo-sidedided mattresses for heavier sleepers should follow this maintenance schedule:

| Time Period | Action Required | Frequency | Purpose |

|---|---|---|---|

| Weeks 1-4 | Rotate head to foot | Weekly | Distribute the initial settlement evenly across all four surfaces |

| Months 2-12 | Rotate head to foot AND flip top to bottom | Monthly | Different sleeping surface every two weeks prevents localised wear |

| Year 2 onwards | Rotate and flip | Every 6-8 weeks minimum | Maintain even wear distribution across all surfaces |

This rotation schedule prevents localised wear developing in your primary sleeping position, which is the main cause of premature body impressions in heavier users.

Mattress protectors and care

Waterproof mattress protectors

- Importance: Essential regardless of weight, particularly important for heavier sleepers

- Reason: Heavier sleepers may perspire more during sleep

- Type to choose: Breathable membrane protectors

- Avoid: Vinyl protectors that retain heat

Toppers for surface protection

- Benefit: Protectsthe mattress surface whilst addingan extra comfort layer

- Maintenance: Washable for easy cleaning

- Replacement cycle: Every 3 to 4 years, rather than replacingthe entire mattress

- Cost savings: Extends mattress lifespan significantly

Vacuuming and freshening

- Frequency: Monthly vacuuming removes accumulated dust and skin particles

- Heavy sleeper note: Particles accumulate faster with heavier use

- Professional cleaning: Annual deep cleaning extends upholstery lifespan

- Benefit: Maintains hygiene and material performance

Custom spring tension specification

One size genuinely doesn’t fit all when body weights span 10 to 35 stone. Our standard spring tension options (soft 1.28mm, medium 1.4mm, firm 1.6mm) suit most customers, but heavier sleepers often require custom specifications beyond these standard options.

We manufacture mattresses using 1.8mm and occasionally 2.0mm gauge springs for customers whose weight exceeds our standard firm tension capacity. This isn’t a standard product you can select from a dropdown menu; it requires direct consultation to ensure the appropriate specification.

The process is straightforward:

- Contact us with your weight, sleeping position, and any existing mattress issues

- We calculatethe appropriate spring gauge and upholstery specification

- We quote custom pricing (typically 10 to 15% above standard models)

- We manufacture to your specification with a 4 to 6 week lead time

Custom specification applies primarily to our Artisan range, where the underlying construction supports heavier-gauge springs. Budget ranges using thinner upholstery and cheaper materials can’t accommodate the firmest spring tensions without creating uncomfortable sleeping surfaces.

What high street retailers won’t tell you?

Having spent 25+ years manufacturing mattresses and consulting with customers of all sizes, here are the inconvenient truths high street retailers avoid mentioning:

Their weight limits are aspiration, al not tested

- The claim: 18 stone weight limit sounds reassuring

- The reality: Assumes optimal conditions, perfect rotation, and supportive foundations

- Actual performancReal-worldrld use for heavier sleepers fails within 2 to 3 years

“Firm” tension is relative to average weight

- Design assumption: “Firm” calibrated for 14 stone sleepers

- Reality for heavy sleepers: Feels medium to soft for 20 stone sleepers

- Why: Heavier bodies compress upholstery more deeply

- The deception: Retailers claim they’re providing firm support when they’re not

Warranties specifically excludeweight-relatedd failure

- Read the small print: Most warranties cover manufacturing defects only

- Exclusion clause: “Normal wear” or body impressions under 3cm excluded

- Heavy sleeper reality: 3cm impressions develop naturally as materials compress beyond elastic limits

- Outcome: Your warranty claim will be denied

One-size-fits-all recommendations harm relationships

- Common scenario: Couples with significant weight differences

- Retailer solution: Single firm mattress for both

- Result: Neither person sleeps optimally

- Reality: Retailers prioritise closing sales over solving problems

Cheap pocket springs area false economy

- Budget specification: Thin gauge springs (1.2 to 1.4mm) and minimal upholstery (1000 to 1500 GSM)

- Performance for heavy sleepers: Will fail prematurely regardless of marketing claims

- Replacement cycle: 3 to 4 years maximum

- Total cost: More than investing properly initially

Realistic budgeting for mattresses that last

Quality mattresses engineered for heavier sleepers cost more than standard models because engineering proper weight support requires more expensive materials and construction. Here’s realistic pricing for mattresses that will actually last:

| Price Range | Weight Suitability | Specifications | Expected Lifespan | Cost Per Year |

|---|---|---|---|---|

| £1,500 to £2,000 | 18 to 20 stone | Entry point specialist mattresses. Firm pocket springs, adequate upholstery, and two-sided construction. | 8 to 10 years with proper care | £150 to £250/year |

| £2,000 to £3,000 | 20 to 25 stone | Mid-range specialist construction. Natural fibres, calico springs, two-sided construction, higher GSM. | 10 to 12 years | £167 to £300/year |

| £3,000 to £5,000 | 22 to 28 stone | Premium natural fibre mattresses with custom-specified springs. Maximum durability materials. | 12 to 15 years | £200 to £417/year |

| £2,000 to £3,500 | 25+ stone (bariatric) | Bariatric Foam mattresses with replaceable topper systems. The base unit is extremely durable; toppers are renewable. | Base: 12+ years Toppers: 4-6 years |

£167 to £292/year |

Cost comparison reality: A £2,500 specialist mattress lasting 12 years costs £208 per year. An £800 standard retail mattress lasting 3 years costs £267 per year whilst providing inferior support throughout its shortened lifespan. The specialist mattress costs less per year while delivering superior comfort throughout its lifespan.

Trial periods and realistic expectations

Our 60-day trial period allows you to properly assesswhether a mattress works for your specific needs. For heavier sleepers, here’s what to evaluate during the trial:

| Time Period | What to Expect | What to Check |

|---|---|---|

| Weeks 1-2 | Initial settlement is normal. The mattress will soften slightly as the materials conform to your body shape. | Don’t judge final comfort yet. This is an adjustment period. |

| Weeks 3-4 | The mattress should feel consistent night to night. | Check for proper spinal alignment. Note any morning back pain. Press the mattress to check you’re not contacting the springs directly (bottoming out). |

| Weeks 5-8 | Long-term comfort becomes apparent. Should sleep through the night without position-related discomfort. | Look for any visible body impressions. Check edge support. Assess whether you’re getting quality sleep. |

Warning signs within 60 days (not normal):

- Body impressions exceeding 2cm depth: Mattress isunderspecifiedd for your weight

- Persistent pressure points: Firmness mismatch with your sleeping position

- Bottoming out onto springs: Insufficient upholstery GSM for your weight

- Morning back pain: Inadequate support or wrong tension specification

If these issues occur during the trial period, contact us immediately. We can assess whethera different spring tension or model specification would perform better.

Choose engineering over compromise.

The mattress industry has failed heavier sleepers for decades by treating them as edge cases rather than designing proper solutions. High street retailers stock one token firm model and pretend it solves all problems. Online mattress brands ignore the segment entirely, focusing on “universal comfort” that works poorly for anyone in particular.

Heavier sleepers deserve mattresses engineered for their actual requirements: appropriately gauged springs, adequate upholstery GSM, two-sided construction for longevity, and honest weight capacity ratings. These specifications cost more to manufacture, which is precisely why most retailers avoid them.

We’ve spent 25+ years specialising in properly specified mattresses because we refuse to accept that 40% of the UK population above 14 stone should make do with inadequate products. The Resilience range, Artisan Bespoke with custom spring tensions, and our willingness to manufacture outside standard specificationsexists because engineering proper solutions is what manufacturing actually means.

You shouldn’t compromise on sleep quality because retailers haven’t bothered to engineer for your needs. Contact us to discuss your specific requirements, whether that’s a 19-stone back sleeper needing firm support, a 24-stone side sleeper requiring pressure relief, or a 30+ stone sleeper requiring bariatric specifications.

We’ll specify mattresses that work rather than sell you the firmest model we have in stock.

We want to be sure you’re happy with your mattress, which is why we offer a 60-day ‘Love It or Return It’ guarantee. We’ll come and collect the mattress free of charge and offer a full refund if you’re not satisfied within the first 60 days.

For more information on pocket sprung mattresses, get in touch on 0161 437 4419.

Dreaming of the perfect nights sleep?

Ask us a question

There are over 6000 questions and answers submitted by you on all questions about mattresses and bed problems. Enter a keyword such as Vi Spring, John Lewis beds, bad back or Memory Foam and see if your question has already been answered.

If you can’t find an answer in knowledge hub, ask a new question. We aim to respond to all questions within one working day.

Newsletter

Enter your email to join our newsletter. We’ll send you occasional news and mattress expertise.