Open Coil vs Pocket Sprung Mattresses Explained

Updated 2022: We often get asked what are the differences between open coil and pocket sprung mattresses are. The quick answer is comfort! The open coil or cage sprung mattress spring-type will leave you restless, uncomfortable and probably moving to sleep on the sofa. Whereas a quality Pocket spring mattress can individually contour to you offering a perfect nights sleep.

Let’s look at open coil beds in more detail.

Open Coil Bed Guide

- What is an Open Coil mattress?

- Is an Open Coil mattress for me?

- Examples of Open Coil mattresses

- Disadvantages of an Open Coil mattress

- How much is an Open Coil mattress?

- Why you should choose Pocket Springs

- Benefits of Pocket Springs

- How to test a mattress to see if its Open Coil or not

What is an Open Coil Mattress?

Open coil beds use one continuous thread of metal that’s twisted in loops to create one massive bouncy spring.

Open coil mattresses are the very worst of all spring units in mattress showrooms. We say this with a hope that no one falls for such a mattress unless they absolutely have to. They are made from one continuous coil of wire that is then spun into coils – which look like large loose springs.

These coils are then attached to wireframe and act as one huge spring. There is no separation or independence from the spring, if you bounce on one side the other side bounces too!

Open Coil also goes by the names of:

- Open coil

- Continuous coil

- Interconnected coil/spring

- Cage sprung

- Bonnell sprung

- Miracoil

- True coil

- Orthopaedic sprung

There’s a huge marketing exercise around spring support in mattresses and beds. So much so that retailers are forever inventing new spring terms, huge spring counts and endless spring ‘technology’.

Open coil mattresses are often marketed as good for bad backs offering excellent firm support. However, we’re going to show you exactly why this is false and you should avoid an open coil mattress of interconnected mattress springs.

Is an Open Coil mattress for me?

There’s only one reason for using an open coil in a mattress and that is price. These springs should be reserved for the very cheapest and basic of mattresses under £250.

The reason that open coil/cage sprung units are used is that they are quick to mass-produce and import. As the whole unit can be compressed and then stacked. It takes virtually no effort to then place some upholstery on top, usually just a recycled grey pad and then glued or stitched together. Quick, cheap and basic. There’s nothing wrong with this if you’re paying the very least amount for a mattress.

You may read other sites discussing the benefits of a firm open coil mattress but unless you’re restricted by the tightest of budgets you should always opt for a pocket sprung unit instead. Open coils offer practically zero individual support for sleepers.

Examples of Open Coil Mattresses

Dreams & Bensons Beds have a number of open coil mattresses which they have rebranded as ‘traditional spring’ mattresses. Probably due to the fact that cage sprung or open coil doesn’t sound as alluring! Here are some examples of cage sprung mattresses.

- Silent night Miracoil Cushion Top Mattress

- Turner Traditional Spring Mattress

- Sealy Rutherford Traditional Spring Mattress (they call their open coil as Posturetech support)

- Quebec mattress

- Sealy Vitality

- Sealy Activesleep

Benefits of open coil beds

- They are cheap to produce and lightweight

Drawbacks of open coil mattresses

- Spring unit causes transference so when once sleeper moves the entire mattress moves with it

- Large gaps between the spring units often cause upholstery to migrate between the gaps

- No tailoring for bodyweight or two different sleepers

- Zero edge support

- Side bulging is common

How much is an open coil mattress?

Open coil mattresses are usually found at the £250-£400 price range. If you’re paying more than this for a mattress you shouldn’t have to endure an open coil spring system in a mattress.

Have a look at our Origins range to see what to expect from a mattress from the £500 mark. Which should always be pocket sprung!

Some dubious retailers are hiding the fact their mattresses are cheap open coil models

Why Pocket Springs are superior to Open Coils

Pocket springs are a world away from the open coil offering. A pocket spring is an individual spring that is then encased in either a synthetic, in most mattresses, or in the very top end, calico encasing.

Each pocket spring works independently so when one sleeper moves the other springs don’t all follow suit like an open coil model. This allows for a much more advanced reaction from the spring allowing micro-adjustments to be made based on your body shape, sleeping position and nocturnal movements.

Pocket springs also allow far more edge support if you prefer to sleep near the edge of your mattress. Whereas an open coil model will simply tip you out as the sides of the mattress have no edge support like a hand made pocket spring model.

Pocket springs can also be tailored to your body weight and a split tension or zip & link model can have two different tensions in one mattress. Making pocket springs ideal for two different weighted sleepers. This can never be achieved with an open coil mattress.

Pocket springs also provide a much more consistent surface for the comfort layers made of fibres and upholstery to sit on. When placing fibres on top of an open coil system more often than not they fall in-between the gaps over time creating a very lumpy and bumpy sleeping surface.

Do Pocket Springs last longer than open coil/cage sprung beds?

A pocket spring mattress will far outlast a cage sprung model and provide years of quality sleep when upholstered with high grams of fibres. This is because the springs are independent meaning each one can work on their own vs the open coil single spring. Meaning that an open coil takes all of the stress each night in the same place.

Leading to excess wear on certain parts of the spring which can lead to mattress sagging and dipping.

Benefits of a Pocket Spring Mattress

- Independence between each spring offers unparalleled support where you need it

- Completely flexible for sleeping style

- Zero transference (especially used in a Zip & Link model)

- Long life span due to greater support overall

- Edge support can be achieved with higher-end models

Are Pocket Springs more expensive?

Pocket Springs are more expensive than a cage sprung model – you won’t get a real pocket spring model for under £350 for example. However, if you’re paying £500 upwards for a mattress then the very least you should expect is a synthetic pocket spring support system.

It’s at this price point that other retailers are starting to rename open coil springs in the hope you won’t notice. At this price point, you absolutely should not have to accept such as basic support system in your bed.

| How much to spend on a double mattress? | What can I expect for my money? |

|---|---|

| Under £500 | Will not get you much at best a 13.5 gauge open coil/cage sprung with a thin polyester layer or a solid foam mattress. |

| £500 | Entry level spunbond springs with some form of synthetic upholstery. Usually one sided mattresses. |

| £750 | The beginnings of a basic pocket springs unit with 800 – 1000 count. No substantial amount of filling other than foams and synthetic materials. Two sided models. |

| £1000 | Should get you away from most low ranges and into the mid-range pocket spring models. |

| £1250 | Should get you a decent pocket sprung mattress with some Natural Fibre content. |

| £1500 | Should get you many manufacturers mid-range models with Natural Fibres |

| £1500-£2000 | Should get you a Hand Made primarily Natural Fibre Quality Mattress |

| £2000+ | You should expect 100% Natural Fibres and Traditional Hand Made Construction Method. |

| £5000+ | A Bespoke Hand Made Sleep System, High-end Spring Units & Featuring the Worlds Most Luxurious Natural Fibres. |

How can I tell if a mattress is an open coil?

Firstly you can ask the retailer if it’s a pocket spring or open coil support system.

If they can’t tell you the mattress description is always a good place to look. If you can’t see the term pocket spring and there’s a reference to a ‘continuous spring’ then it is more than likely an open coil spring.

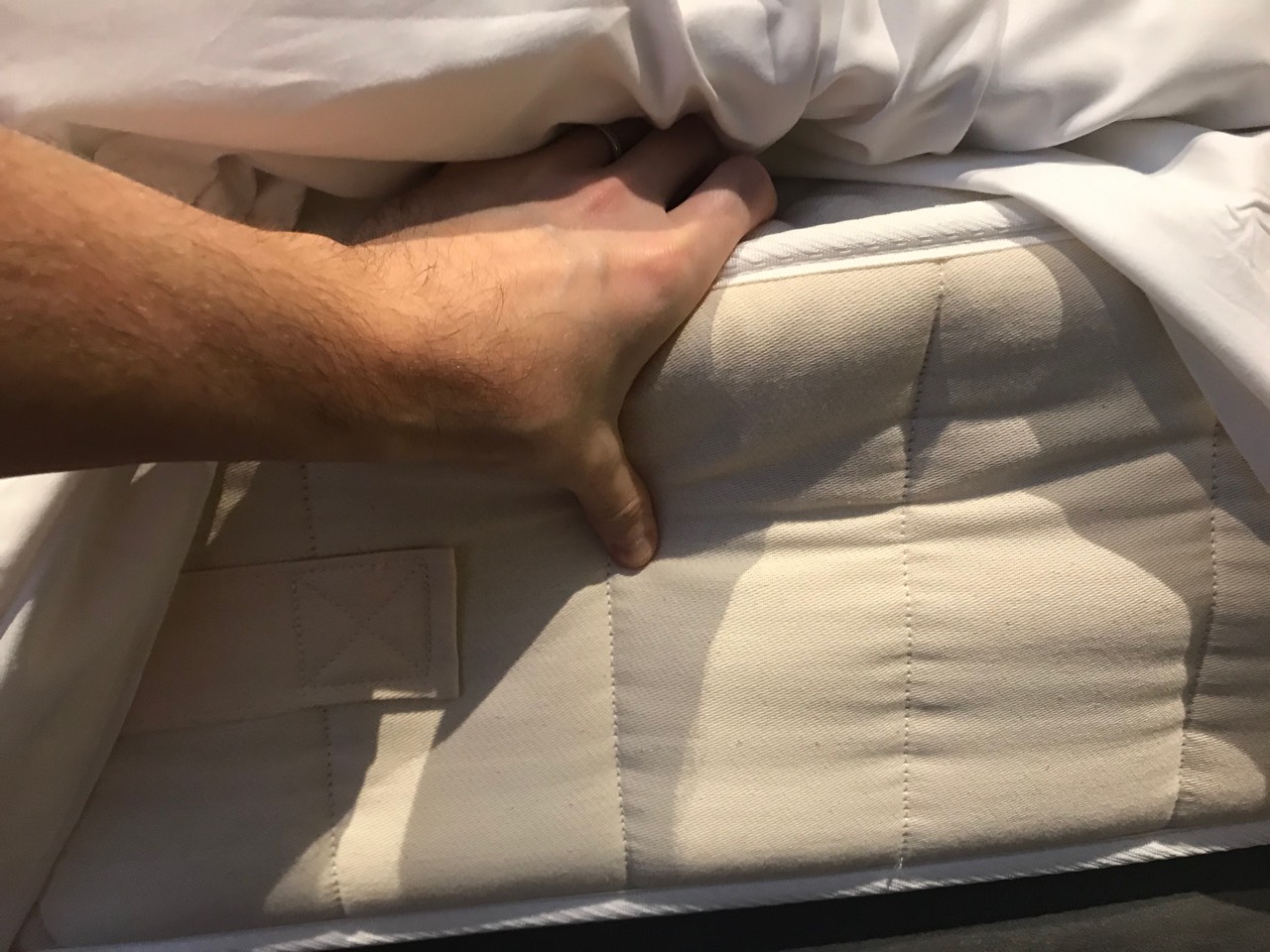

Lastly, you can do a quick test to identify a cage sprung or open coil mattress.

Simply grab the side panel of the bed like the image below. If you can feel thick wire and push your fingers in between then it’s an open coil spring. Any decent pocket spring system won’t allow this as there is wadding and the spring cases to stop you from doing this.

Unless you’re really limited by budget, under £300, then there should be no reason why you should choose an open coil spring when there are far better pocket springs available at the same price point. Pocket springs will last far longer, offer better support and comfort over the life of your mattress.

If you’re stuck trying to choose a mattress then why not let our small expert team provide some tailored advice? That way you can avoid costly mistakes and ensure you’re getting the best mattress for your budget.

Ask us a question.

There are over 6000 questions and answers submitted by you on all questions about mattresses and bed problems. Enter a keyword such as Vi Spring, John Lewis beds, bad back or Memory Foam and see if your question has already been answered.

You can filter popular questions by the categories below. If you can’t find an answer, ask a new question below. We aim to respond to all questions within one working day.

Mattresses

Mattresses  Take our mattress quiz

Take our mattress quiz  Contact

Contact  About us

About us